You will find in this section the causes and remedies to the main problems related to timing belts: clean break, ragged break, loose teeth, side wear, worn land area, irregular wear on belt back, worn teeth, cracks on the belt back, tooth swelling.

Clean break

Causes:

- Incorrect handling during installation

- Use of inappropriate tools during installation

Actions:

- During the installation operations, do not twist or bend the belt excessively

- During assembly, do not use inappropriate tools or levers to fit the belt on the pulleys; if there are flanges on the pulleys, do not force the belt and fully loosen the tensioner to guarantee minimum amplitude of the belt

- Replace the faulty belt

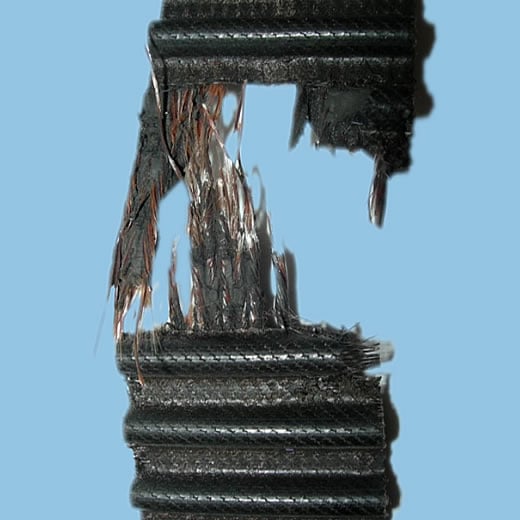

Ragged break

Causes:

- Penetration of foreign matter in the transmission

- Locking of a transmission component

- Excessive assembly tension

- Contact with fuel, petroleum derivatives or solvents

Actions:

- Check the correct fastening of the transmission components and protective case, and its integrity

- Check the wear condition of the components and verify their correct operation

- Tension the belt correctly

- Replace the faulty belt

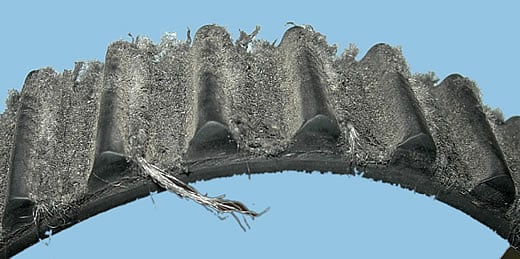

Loose teeth

Causes:

- Low working tension of the belt

- Loss of tension in the belt

- Penetration of foreign matters in the transmission

Actions:

- Check the belt tension and tension it correctly

- Check the integrity and correct fastening of the tensioner and other transmission components

- Replace the faulty belt

Side wear

Causes:

- Misalignment of the tensioner or one of the transmission components

Actions:

- Check the integrity and correct fastening of the tensioner and other transmission components and reset the alignment if necessary

- Replace the tensioner and/or pulley if worn

- Replace the faulty belt

Worn land area

Causes:

- Excessive tension

- Worn pulleys

Actions:

- Replace the worn rigid component

- Replace the belt and reset the correct working tension

- Replace the faulty belt

Irregular wear on belt back

Causes:

- Locking of a transmission component

- Worn pulleys

Actions:

- Replace the worn rigid component

- Replace the belt and reset the correct working tension

- Replace the faulty belt

Worn teeth

Causes:

- Irregular tension

- Pulleys with worn teeth

- Belt tooth profile not compatible with the pulley notches

Actions:

- Reset the correct belt tension

- Replace the worn rigid component

- Check compatibility between the belt tooth profile and the pulley notches

- Replace the faulty belt

Cracks on the belt back

Causes:

- Operation at excessively high or low temperatures

Actions:

- Check the working environment temperature and use belts produced with heat-resistant compounds

- Replace the faulty belt

Tooth swelling

Causes:

- Contamination by solvents, lubricants or coolant

Actions:

- Handle with clean hands as much as possible

- Remove any contaminant leakage from the engine

- Replace the faulty belt